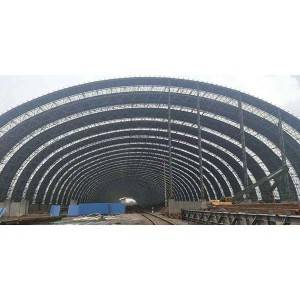

Partial display of company products

Partial display of company products

With the development of science and technology, the application of steel structures in construction engineering in the world is more and more extensive. Welding is a very important processing technology in steel structure manufacturing. According to statistics from industrialized countries, the steel used only after welding accounts for about 45% of the steel output every year. By the end of 1980s, welded steel structures had accounted for 30% of the steel output in China.

China's steel output was 80 million tons in 1992 and reached 94 million tons by the end of 1997. According to the development trend, China's steel output will soon exceed 100 million tons after entering the new century.

Features of steel structure:

Hot-rolled section steel (angle steel, I-steel, channel steel) steel pipes, steel plates, cold-worked thin-walled section steel and steel cables are used as basic components. After the basic components are connected according to certain rules by welding, bolt or rivet connection, the basic components are irregularly connected into structures capable of withstanding external loads as steel structures by welding, bolt or rivet connection.

① High strength and small mass. The strength of steel is many times higher than that of wood, masonry, concrete and other building materials. Therefore, when the load and conditions are the same, the structure made of steel has smaller dead weight, smaller required cross section and more convenient transportation and erection.

② Good plasticity and toughness. Steel has good plasticity. Under normal circumstances, it will not cause sudden fracture and damage due to accidental overload or local overload, but will have large deformation warning in advance, so that remedial measures can be taken. The steel also has good toughness and strong adaptability to the dynamic load acting on the structure, providing reliable guarantee for the safe use of the steel structure.

③ The material is uniform. The internal structure of the steel is uniform, and the physical and mechanical properties in all directions are basically the same, which is very close to isotropic bodies. Within a certain stress range, the steel is in an ideal elastic state, which is in good agreement with the basic assumptions adopted by engineering mechanics, so the calculation results are accurate and reliable.

④ It is convenient to manufacture. The steel structure is composed of various processed sections and steel plates, which are manufactured into basic components by welding, bolts or rivets, and transported to the site for assembly and splicing. Therefore, the manufacture is simple, the staging period is short, the efficiency is high, and the repair and replacement are also convenient. This construction method of factory manufacturing and site installation has the advantages of mass production of large pieces and high precision of finished products, and at the same time creates conditions for reducing cost and bringing into full play the economic benefits of investment.

⑤ Poor corrosion resistance. Steel structures made of ferrous metals are easy to rust in the air, especially in high humidity or corrosive medium, so they need frequent repair and maintenance, such as derusting and coating. The maintenance cost is relatively high.

⑥ Poor high temperature resistance. Steel is not resistant to high temperature. With the increase of temperature, the strength of steel will decrease. In a fire, the unprotected steel structure can only last for about 20min, so fire prevention measures must be taken for important steel structures, such as wrapping concrete or other fire prevention materials outside the steel structure, or spraying fire prevention coatings on the surface of components.

For the display of semi-finished products before painting, all construction shall be completed according to the drawing number, and the number indicates that in the non-painting parts, regardless of transportation or installation, the factory shall be delivered according to the number sequence

Product 1

Product 3

Product 2